PTFE Spares

Product Details:

- Size Available in Various Sizes

- Diameter Customizable

- Surface Finish Polished / Smooth

- Noise Level Zero / Silent Operation

- Usage & Applications Used as spare parts in valves, pumps, and chemical machinery

- Shape Ring, Bush, Sheet, Custom Shapes

- Capacity Application Dependent

X

PTFE Spares Price And Quantity

- 10 Piece

PTFE Spares Product Specifications

- Customizable as per requirement

- PTFE (Polytetrafluoroethylene)

- Polished / Smooth

- Machined Precision

- PTFE Spares

- Customizable

- Available in Various Sizes

- Used as spare parts in valves, pumps, and chemical machinery

- White

- Lightweight; Dependent on Size

- Manual / Mechanical

- Suitable for High Pressure Applications

- Application Dependent

- Ring, Bush, Sheet, Custom Shapes

- Smooth Finish

- Zero / Silent Operation

PTFE Spares Trade Information

- Cheque, Cash in Advance (CID)

- 500 Piece pices Per Month

- 1 Days

- As per standard

- All India

Product Description

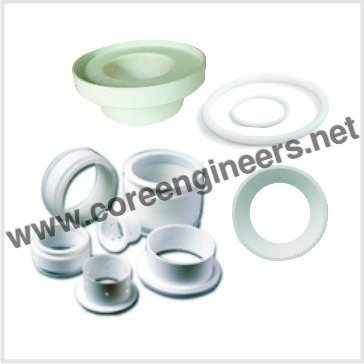

PTFE Spares

With the support of our highly experienced and skilled workforce, we are renowned as one of the well equipped traders, suppliers and exporters of PTFE Spares. These spares are used to manufacture valves such as ball valves & fbv, sleeve for butterfly valve & lug valves. Our offered range of product is known for dimensional accuracy, corrosion resistance and easy usage. PTFE Spares is available in variety of shapes and sizes at diminutive prices in the market.

Key Features:

- Accurate Dimensions

- Corrosion Resistance

- Easy to Use

- Available in variety of shapes and sizes

Customizable Precision for Diverse Industries

PTFE spares offer versatility through custom shapes, sizes, and dimensions, ensuring compatibility with specialized machinery in different sectors. Their lightweight yet durable construction, combined with a polished surface finish, provides low maintenance and reliable performance in harsh environments.

High-Pressure Performance and Chemical Resistance

Designed to withstand extreme pressures and aggressive chemicals, PTFE spares excel in challenging settings like chemical processing and fluid handling. Their robust material properties and engineered design reduce wear and contribute to extended equipment life, making them ideal for critical applications.

FAQs of PTFE Spares:

Q: How are PTFE spares manufactured for high precision?

A: PTFE spares are fabricated using advanced machined precision technology, allowing for tight tolerances and customized forms such as rings, bushes, sheets, and more to meet specific industrial requirements.Q: What makes PTFE an ideal material for spare parts in pumps, valves, and chemical machinery?

A: PTFE is valued for its exceptional chemical resistance, durability, and ability to perform under high pressure, ensuring long-lasting, low-maintenance operation in harsh applications.Q: When should I consider replacing PTFE spares in equipment?

A: PTFE spares should be replaced during scheduled equipment maintenance or when there is visible wear, decreased performance, or if theres a change in operating conditions that requires different specifications.Q: Where can these PTFE spares be used most effectively?

A: PTFE spares are most effective in environments where chemical exposure, high pressure, and low friction are critical, such as chemical plants, fluid handling systems, and pharmaceutical manufacturing units.Q: What is the process for customizing PTFE spare parts to specific requirements?

A: Customization begins with client specifications, including dimensions and shape. The manufacturer uses precise machining techniques and quality controls to produce parts tailored for each application.Q: What are the primary benefits of using PTFE spares in industrial machinery?

A: Primary benefits include high chemical and temperature resistance, silent operation, low friction, lightweight nature, and an extended service life, reducing downtime and maintenance costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email